Home > Value chain

UNDERSTANDING OUR BUSINESS AS A BATTERY MANUFACTURER

Value chain

As a French expert in designing and manufacturing custom batteries, we help you define your battery system, from designing the mechanics, electronics, and the associated BMS (Battery Management System) to characterizing the individual cells, performing 100% quality control and safety tests, and assisting you with certification procedures.

We hold direct supply chain relationships – no distributors – with our component suppliers, and we manufacture your batteries in our workshops in France.

We advise you on how to integrate them into your devices and vehicles and share our expertise regarding charging infrastructure implementation rules if you manage a fleet of vehicles. We also continue to provide you with support via our MCO (Maintenance in Operational Condition) service to ensure you can use your batteries in the long term as we integrate our #DesignForRepair approach from the outset of the design stage.

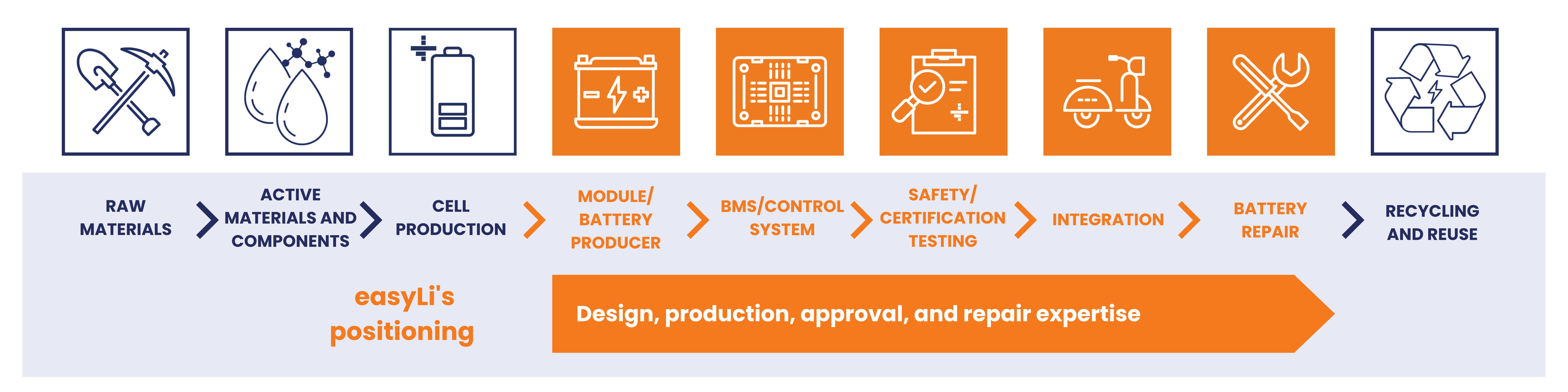

The battery value chain comprises various players with specific expertise. Here is a representation of our strategic positioning within this value chain.

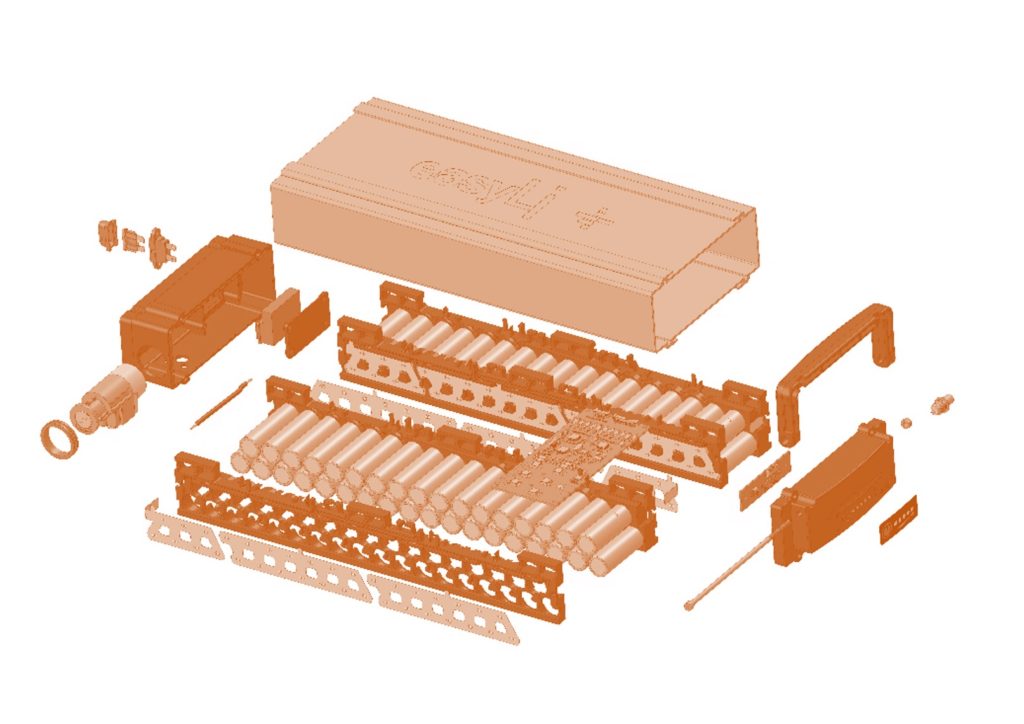

Focused on producing long-lasting and repairable battery systems, easyLi produces batteries in its French factory in Poitiers-Futuroscope:

- Custom-made from 0.5 to 50 kWh

- Standard from 1.8 kWh

easyLi has chosen to specialize in producing intelligent battery systems for the electric mobility and stationary storage markets.

We also use our technology bricks to develop and manufacture battery systems for a wide range of applications.

PROJECT PLANNING

Specifications

Do you have a project? Would you like some help, or do you need help defining your precise requirements? We are here for you, starting with the preliminary study phase, which will allow us to confirm the specifications of your battery system and its environment (charger, communication with the application, mechanical and thermal constraints, etc.).

We will define the battery system that best suits your uses (autonomy, power, dimensions, weight, communication with the device, etc.) for you, integrating your budgetary expectations (DesignToCost) and our know-how in terms of sustainability (DesignForRepair).

THE ADVANTAGES OF OUR BATTERIES

Expert manufacturer of lithium-ion battery systems

Since 2011, we have been designing and manufacturing sustainable lithium-ion batteries for electric mobility and stationary storage for manufacturers and operators of two- to four-wheel electric vehicles, logistics and robotics industries, and building professionals committed to improving their energy performance.

Our solutions are sustainable because they are designed to be easily disassembled and repaired following a high-performance industrial process. We provide Maintenance in Operational Condition (MOC) services for our products to extend their lifetime.

We have a very large library of battery references resulting from the work of our Research & Development laboratory. Our years of experience allow us to advise and support you so that you can move more quickly from design to prototyping, saving precious time for experimenting with prototypes in your applications.

As French experts in designing and manufacturing custom batteries, we help you define your battery pack and system, from designing the mechanics, electronics, and the associated BMS (Battery Management System) to manage your battery, to characterizing the batteries, performing the safety tests, and carrying out the certification procedures for you.

We advise you on how to integrate them into your devices and vehicles and manufacture your batteries in our workshops in France…

Throughout the life cycle of your batteries, we offer solutions to ensure their maintenance in operational condition (MCO) and extend their lifetime. Test bench, analysis, repair, retrofitting, obsolescence management, etc., we provide the support that suits your needs and your market to repair your batteries and assist you in the long term.

Faced with the growth of the battery markets, and especially with a mind toward companies that lease urban two- to four-wheel vehicles, we have opted for a #DesignForRepair approach to facilitate the repair of batteries. Our designs incorporate aspects that facilitate disassembly, allowing access to all the components and simplifying reconditioning. Our industrialized repair process includes test and diagnostic benches dedicated to these operations. Indeed, the batteries from fleets are subjected to high-stress conditions and are often mechanically damaged. In order to make it easier to repair and change them, it is necessary to engineer them with a specific design to facilitate their refurbishment. The aim of this approach is to avoid systematically recycling systems that could be repaired.

Battery safety is a major issue for all manufacturers.

Considering the spacing of the components and designing a safe mechanical architecture integrating thermal constraints and mechanical resistances are reliability guarantees that new manufacturers sometimes neglect.

Our 20 years of experience and the rigor of our 360DesignControl process allow us to also integrate high-performance electronic development, enabling us to adapt the BMS to the electrochemical components, including redundant systems. The safety of your batteries is an absolute priority for our teams.

Subscribe to our newsletter!

Subscribe to our newsletter to be among the first to receive our latest news.